None

Peitian Robot has independently developed a variety of process function packages

They can perfectly meet the operational requirements for grinding、handling、stacking、 arc

welding、 bending and other processes Achieve higher production efficiency

Sheet metal bending Auto-follow function package

the robot can adjust the follow-up angle and displacement in real time by judging

the grating scale or encoder data corresponding to the pressing displacement of

the bending machine slider to achieve synchronization with the bent sheet metal,

greatly improving the quality and efficiency of bending

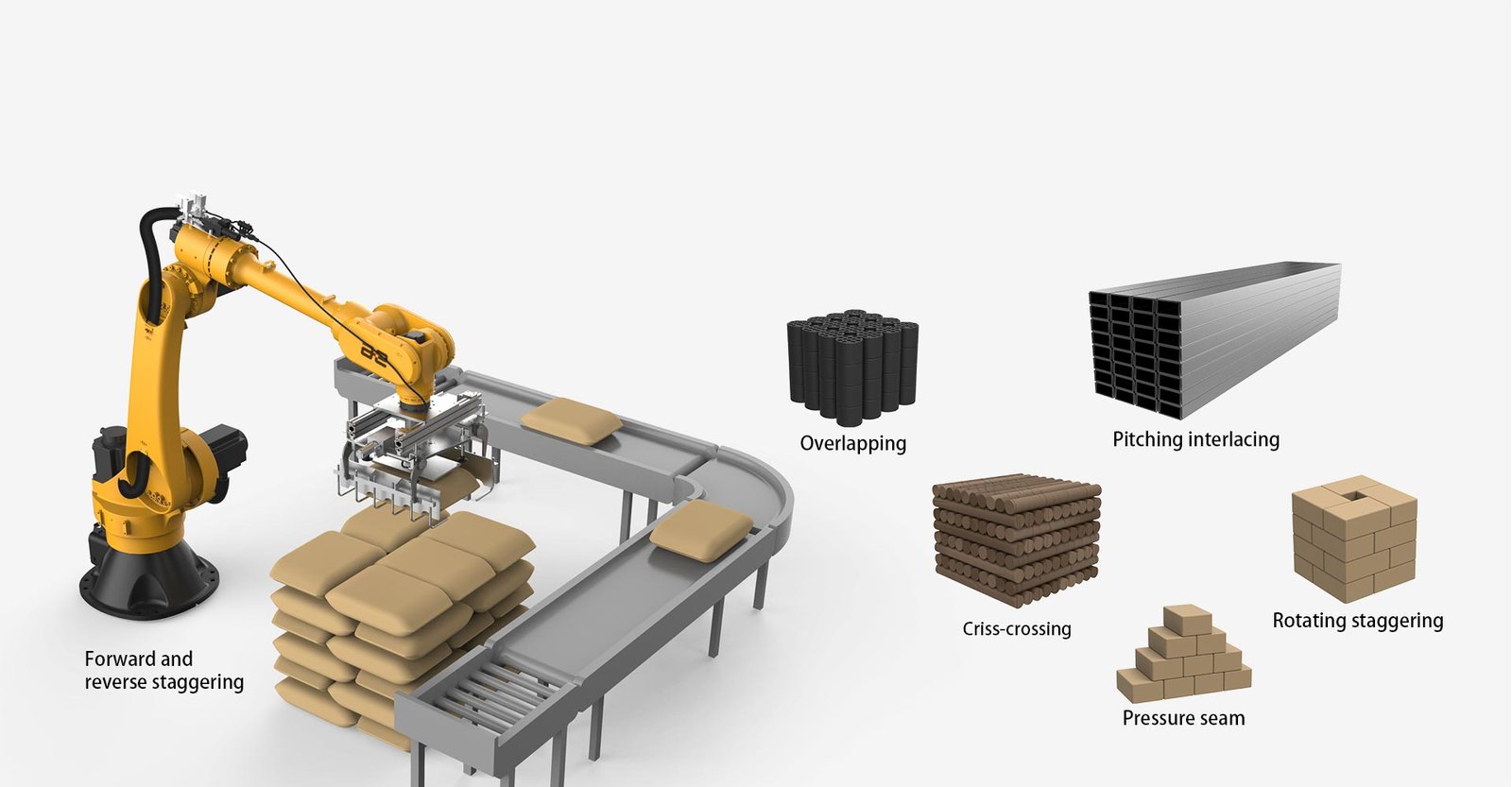

Palletizing Function package

It supports a variety of stacking types such as overlapping、pressure seam、

criss-crossing 、 forward and reverse staggering、 rotating staggering,etc.

Welding process function package

External multi-axis linkage control function

It can achieve linkage welding of ”multi-positioner + multi-robot“

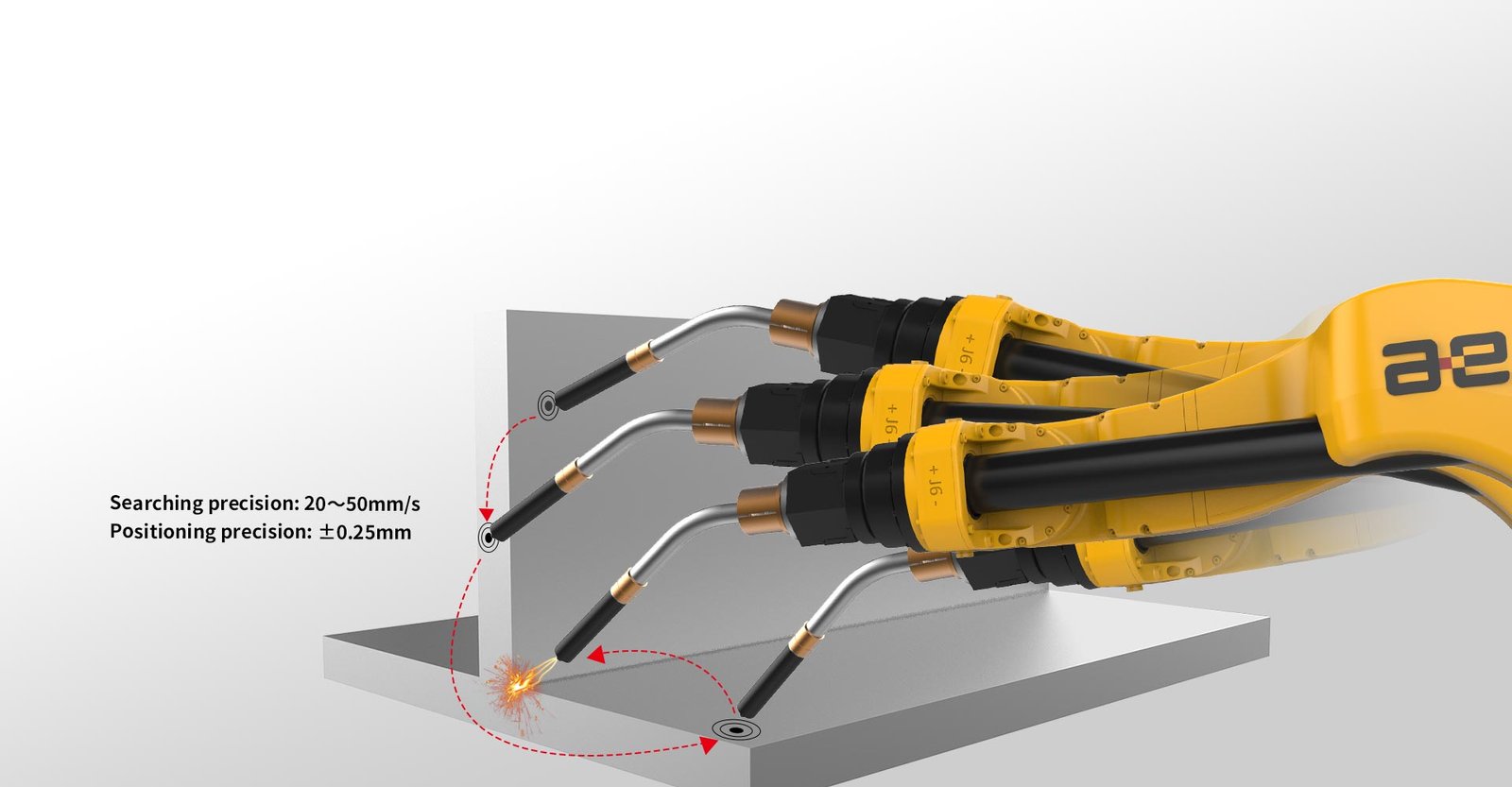

Welding process function package

Low voltage Locating function

Use low voltage to determine the starting point,intermediate point and ending point of straight and curved welds

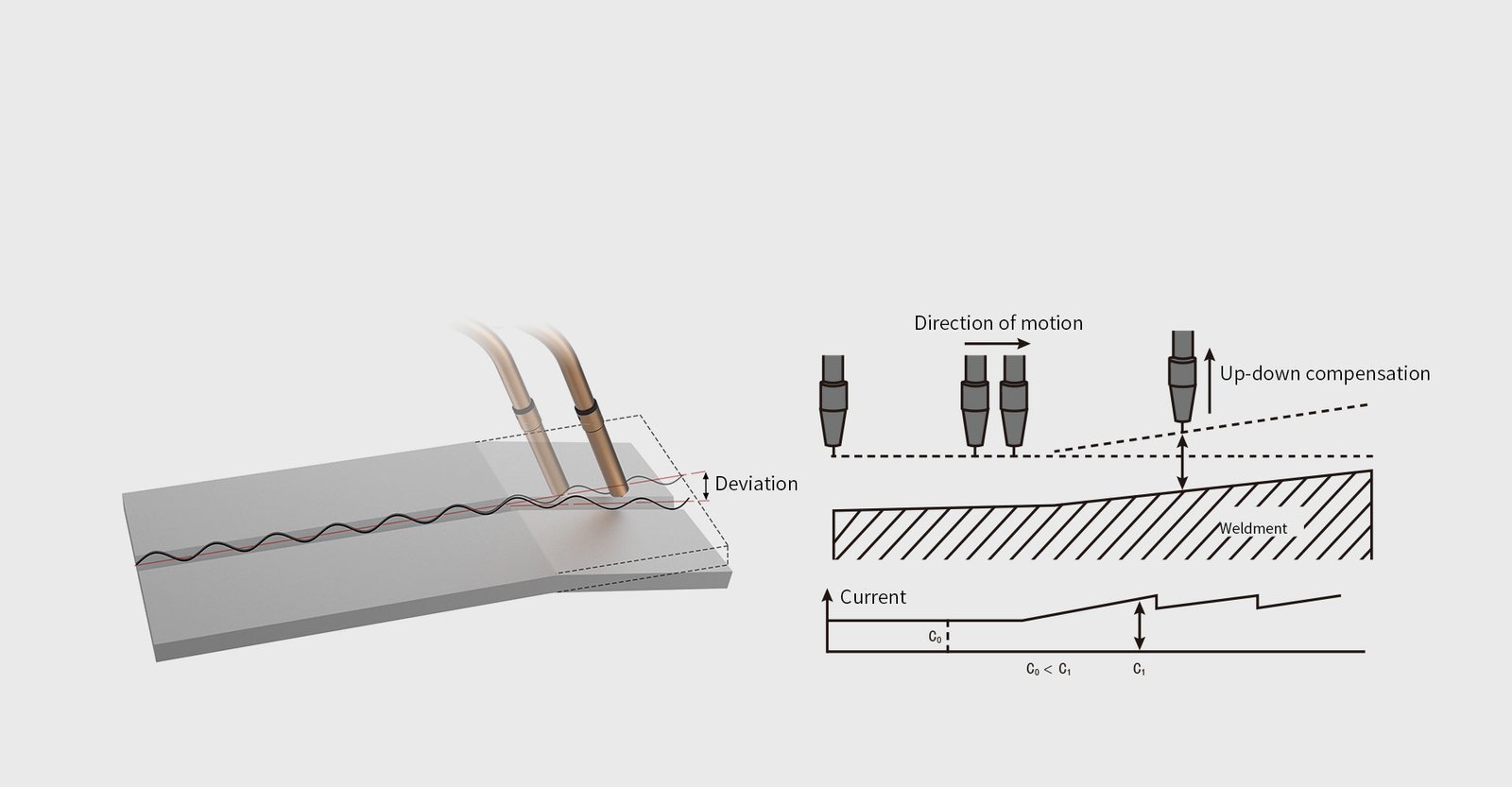

Welding process function package

Swing arc weld tracking function

The welding torch is in sinusoidal swing motion,and the arc is used to detect the change of trajectory

and to compensate up-down-left-right deviation

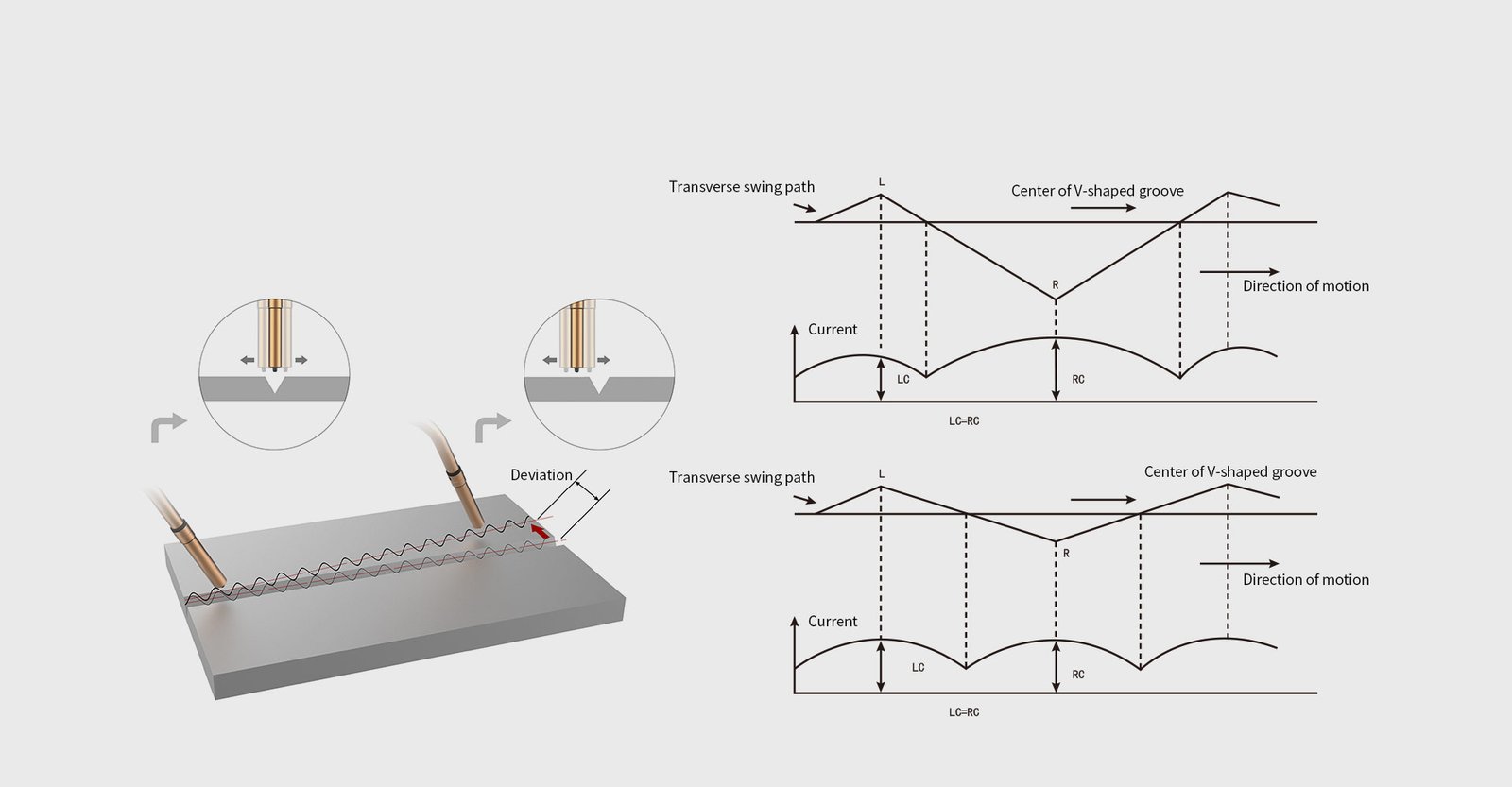

Swing arc weld tracking function

left-right compensation

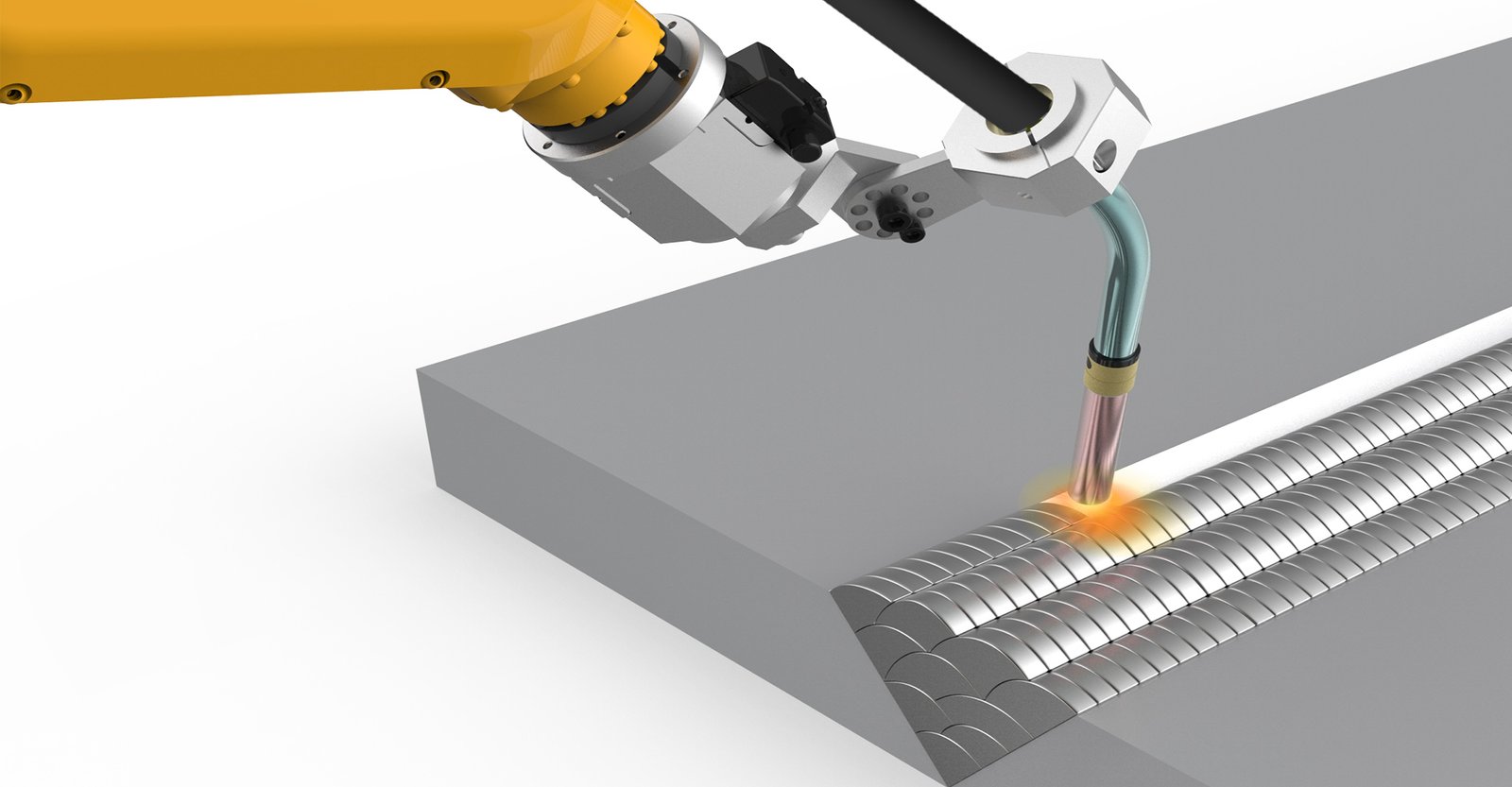

Welding process function package

Multi-layer and Multi-pass Welding

When welding thick plates of 20mm or more,can quickly arrange the welding sequence of the weld bead

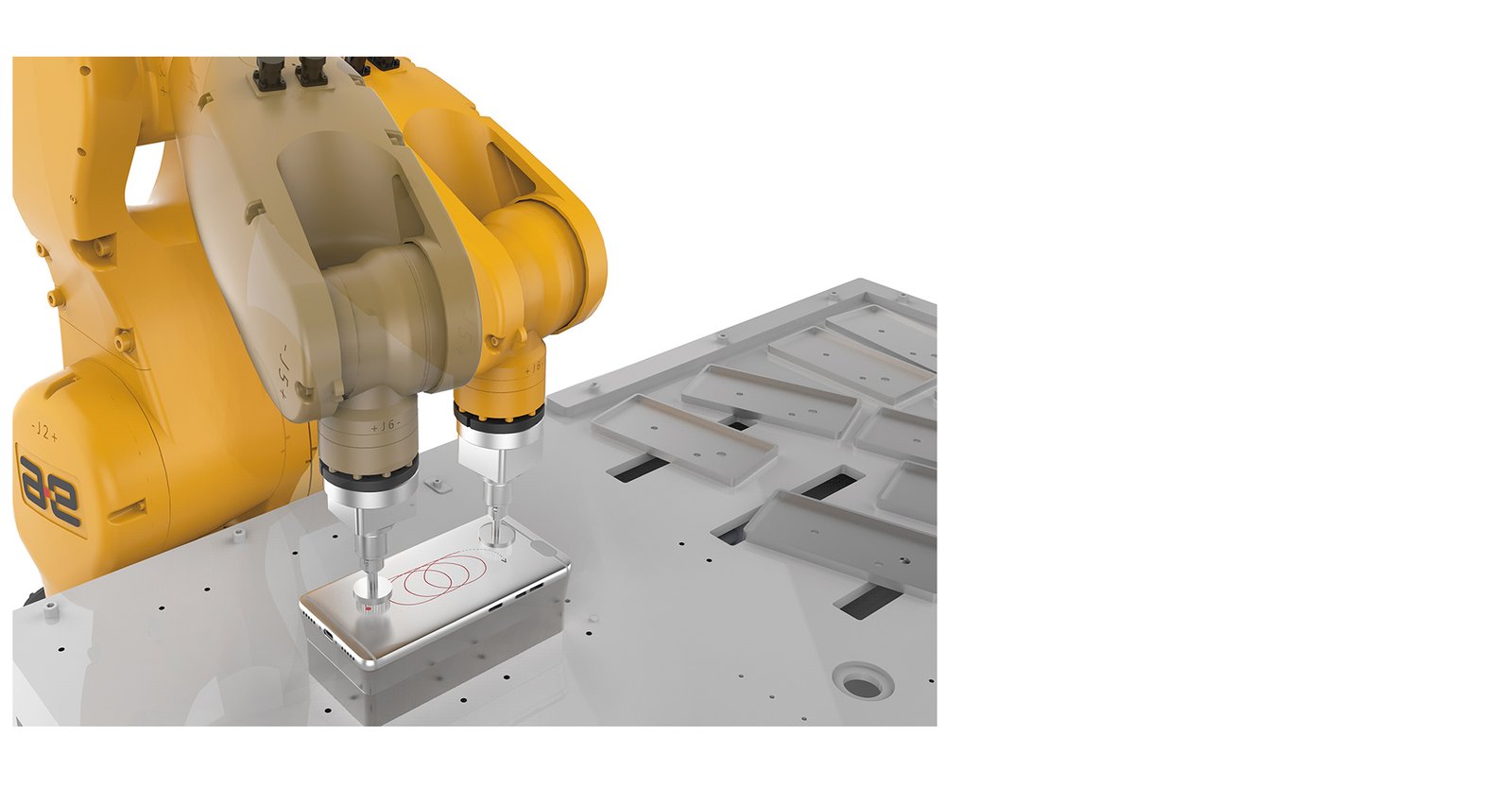

Grinding process function package

Spiral-line interpolation function

Through the setting of parameters such as the number of rotations,direction, pitch and speed,the teaching of spiral trajectory can be easily completed

save more than 40% of the teaching programming time,widely used in the grinding of electronics casings

Grinding process function package

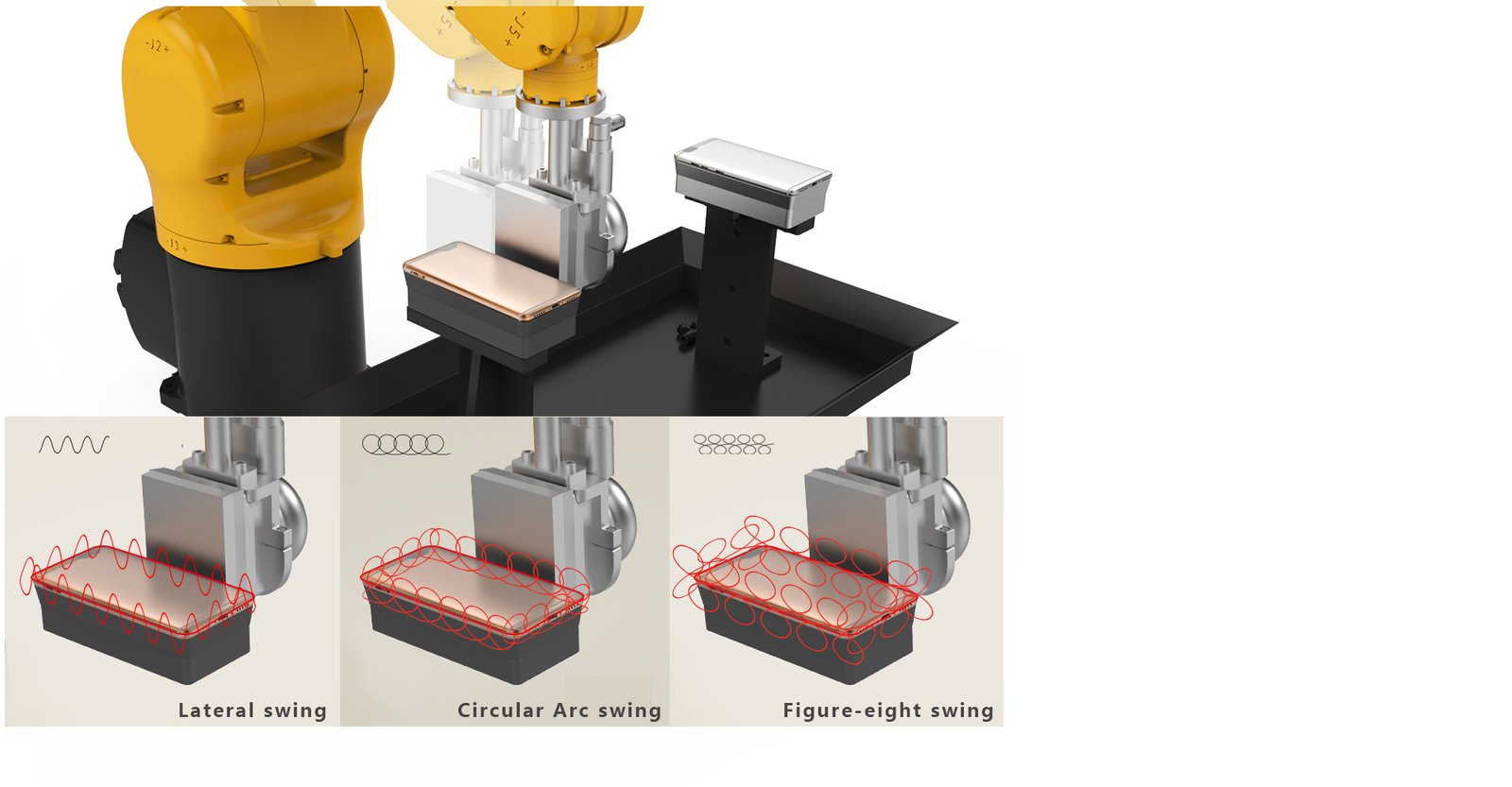

A variety of swing tracks function

A wealth of swing functions to meet the needs of

grinding and arc welding